Understanding the Benefits and Necessity of Fluid Checks

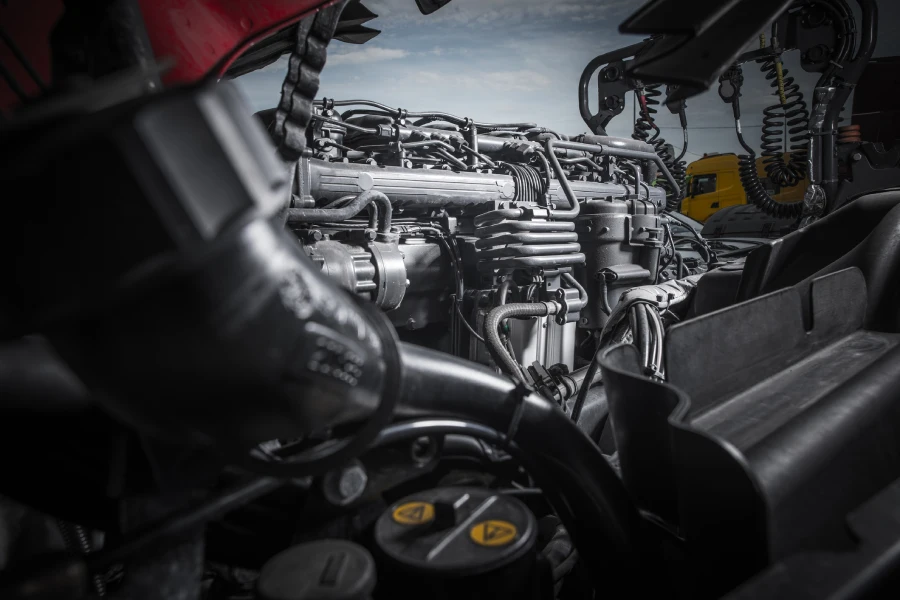

Regular hydraulic fluid checks play a vital role in maintaining machinery efficiency. These checks ensure that your equipment runs smoothly and safely. When hydraulic systems operate with the right fluid levels, they perform better and last longer. Ignoring regular checks can lead to costly repairs or replacements. By understanding the importance of these checks, you protect your investment and enhance performance.

Avoiding Equipment Failure

Failing to conduct regular hydraulic fluid checks can result in unexpected equipment failure. When machines run low on hydraulic fluid, they struggle to function correctly. This strain often leads to breakdowns, which disrupt operations and can be expensive to fix. Furthermore, consistent use without proper fluid levels can significantly wear down components. As a solution, implementing routine checks helps avoid such failures and keeps your operations running smoothly.

Reducing Maintenance Costs

One major advantage of regular hydraulic fluid checks is the reduction in maintenance costs. Routine checks help identify potential issues before they become significant problems. For example, spotting a minor leak early can save you from extensive damage later. Performing these checks minimizes the need for frequent hydraulic repair, saving you both time and money in the long run.

Ensuring Operational Efficiency

Operational efficiency greatly improves with consistent attention to hydraulic fluid levels. Properly maintained systems are less likely to experience downtime. They also work at optimal performance levels, leading to increased productivity. By focusing on regular fluid checks, businesses can streamline their processes and enhance overall efficiency. Moreover, ensuring that machinery does not require unexpected hydraulic repair keeps operations steady and predictable.

Steps for Conducting Fluid Checks

- Identify the specific type of hydraulic fluid required for your system.

- Check fluid levels regularly against recommended standards.

- Inspect for any signs of contamination or discoloration.

- Document findings and schedule follow-up checks as necessary.

Preventing Contamination

Contaminated hydraulic fluid can cause severe damage to your machinery. Dirt, water, and other particles often find their way into hydraulic systems if not carefully monitored. Regular checks help prevent this by allowing timely detection and filtration of contaminants. Keeping fluids clean ensures that your equipment operates efficiently and lasts longer.

Meeting Industry Standards

Adhering to industry standards is crucial for businesses relying on hydraulic systems. Many industries have strict guidelines regarding machinery maintenance, including fluid checks. Regular inspections align with these standards, ensuring compliance and reducing the risk of penalties. Additionally, following best practices fosters trust with clients and partners who expect high operational standards.

Conclusion: Safeguarding Your Investments

Regular hydraulic fluid checks are essential for anyone relying on machinery for daily operations. These checks prevent failures, reduce costs, and boost efficiency. To fully enjoy the benefits, make these checks an integral part of your maintenance routine. Located in Batesville, MS, I specialize in providing top-tier service to maintain your machinery’s peak condition. Reach out at (662) 417-9220 for expert assistance in managing your hydraulic systems’ health with Double R Diesel Repair.